PVC CPVC Soild Extrusion Umbhobho

Izisombululo zokonga iindleko

1. Ukongezwa ngokuthe ngqo-CaCO3

2. Iiyunithi zolawulo eludongeni (izikena)

3. I-Automatic Thermal Centering (ATC)

4. Iinkqubo zeGravimetric (RGS)

SUPX Ukongezwa ngokuthe ngqo-RDA

I-RDA iqinisekisa ukuba ukongezwa kwezinto eziphathekayo kwi-pvc powder kuya kwenziwa ngendlela echanekileyo nechanekileyo.Iyunithi ye-RDA ixhonywe kwi-extruder ukwenzela ukudosa rhoqo kwezinto ezinzima zokuphatha kwindawo yoshishino.Izixa eziphezulu zeCaCO3 zingongezwa ngaphandle kwengxaki yokwahlulahlula.

Izinto eziluncedo kwiinkqubo zeRDA

• Akukho kwahlulwa kweCaCO3 kunye nePVC ngexesha lothutho.

• Umbhobho ogudileyo.

• Ukudibanisa ukonga amandla.

• Ukwenyuka kokuguquguquka komgca we-extrusion (ukwenziwa kwesiseko).

• Ukongezwa kwegravimetric yezongezo.

• Iziphumo eziphezulu kumazinga asezantsi ekwaliwa.

IiYunithi zoLawulo lweWall-Izikena

Ukulawula imilinganiselo yombhobho ngexesha lemveliso yinto ebalulekileyo yokugcina umbhobho kwiinkcazo ezikhethiweyo.i-scanners ziyakwazi ukulinganisa ubukhulu bodonga lombhobho kunye nobubanzi.Uluhlu lweskena ezineempawu ezahlukeneyo ziyafumaneka, ezigquma ubungakanani bombhobho ukusuka kwi-10-1600 mm (1/2” - 60”) ububanzi.

Izinto eziluncedo kwiiskena zethu:

• Ubunzima bodonga olungaphakathi oluqhubekayo kunye nomlinganiselo wedayamitha

• Ubuncinci bolawulo lobunzima bodonga (ukunciphisa ubunzima)

I-Automatic Thermal Centreing-ATC

I-ATC yenza kube lula ukulawula ukuhanjiswa kodonga lodonga.I-ATC inokulungelelanisa ukungafani kobunzima bodonga kwaye ngaloo ndlela inciphise ixesha lokuqalisa umgca wemveliso, ubuninzi bombhobho kunye nezinto ezilahliweyo.

Inkqubo yeGravimetric - RGS

Inxalenye engundoqo ye-RGS yi-hopper yokulinganisa.Emva kokuzaliswa, izinto zihamba ukusuka kwi-hopper yokulinganisa ukuya kwi-extruder.Ilahleko yobunzima kwiyunithi nganye yexesha lilingana nokuthathwa kwezinto ze-extruder.Imveliso ye-extruder efunyenweyo ithelekiswa nexabiso elimiselweyo kunye nenkqubo yokulawula iya kulungelelanisa isantya se-scruder screw (okanye isantya se-dosing) ukuzisa imveliso kwinqanaba elifunekayo.Olu lawulo lugcina imveliso ye-extruder izinzile nangona kukho ukuguquguquka koxinaniso oluninzi lwemathiriyeli ekrwada.

Endaweni yolawulo lwemveliso, isignali yemveliso ingasetyenziselwa ukulawula isantya sokutsala.Kwimeko apho ubunzima bombhobho ngemitha bugcinwe kwinqanaba elihlala lihleli.Xa umgca ubandakanya i-scanner ye-ultrasonic, isiphumo esilinganisiweyo sisetyenziselwa ukulinganisa okuzenzekelayo komlinganiselo we-ultrasonic.Oku kuphelisa ixesha elidla ixesha leenkqubo zokulinganisa ukulinganisa.

Inkqubo yokulawula inkqubo-PCS II

I-PCS II ngokwayo yinkqubo yokulawula enokuthi idibaniswe neiskena, i-ATC, i-RDA, kunye ne-RGS.Uhlobo lwesikena, i-ATC kunyeinkqubo yegravimetric ixhomekeke kumgca we-extrusion.

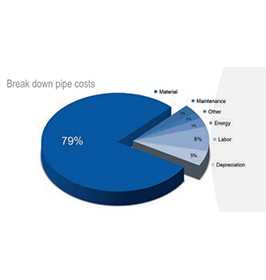

Izinto eziluncedo kwizisombululo zethu zokonga iindleko

• Imbuyekezo egqwesileyo kutyalo-mali

• Ukuncitshiswa kwexesha lokuqalisa kunye nelahleko

• Ujongano lomsebenzisi olunobuhlobo lolawulo olupheleleyo lomgca we-extrusion

• Ukunciphisa umzimba

• Ingasetyenziswa kwisixhobo esele sikhona.